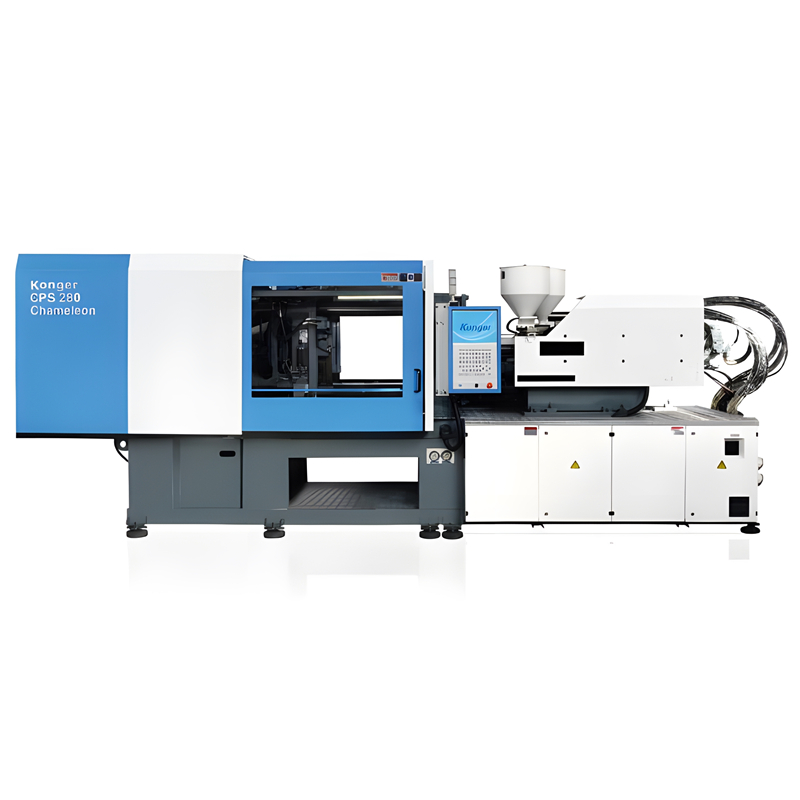

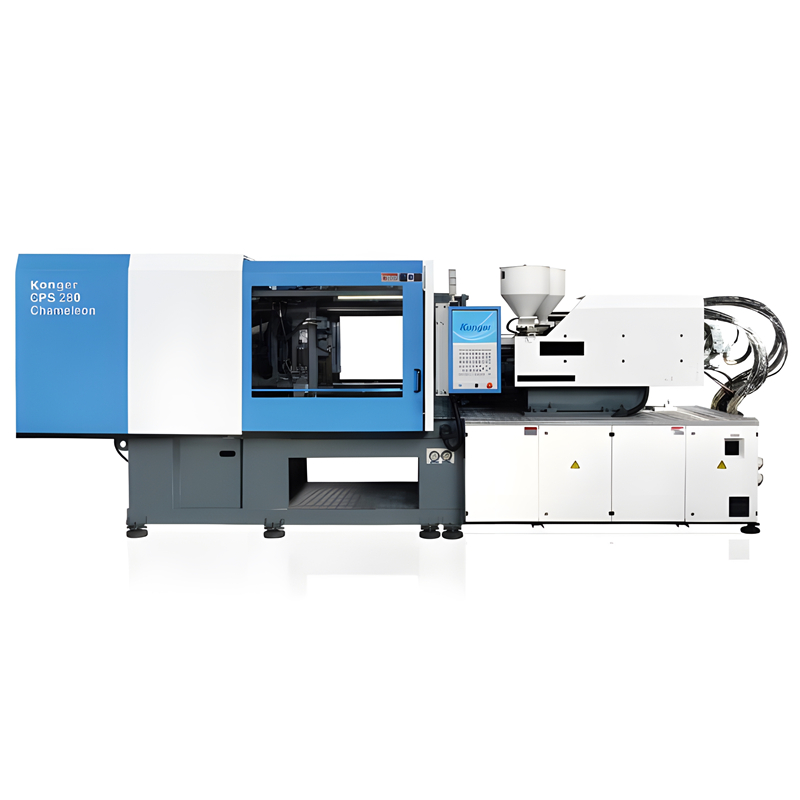

Xameleon-CS seriyali plastik qarshi kalıplama mashinasi

Xameleon-CS seriyali plastik qarshi kalıplama mashinasi

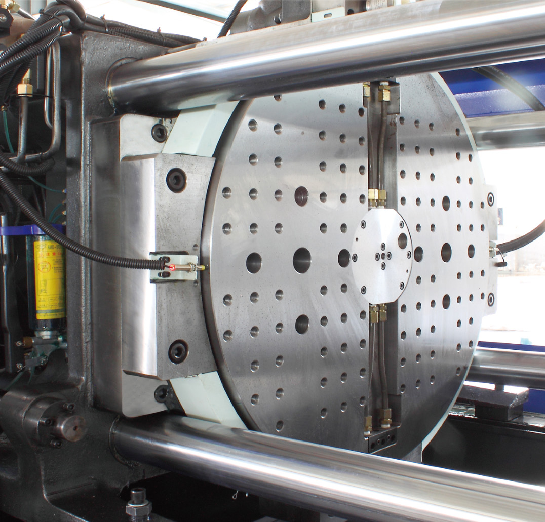

Mahsulot afzalliklari

● Samarali Servo Gear uzatish tuzilishi barqaror va aniq pozitsiya bilan yuqori tezlikda aylanishni davom ettiradi.

● Bog'lash va chiqarish yo'riqnomasida ishlatiladigan grafit mis gilza.Harakat plitasi va oxirgi plastinkada ishlatiladigan grafit mis blokli yostiqlar tez va aniq qoliplarni ochiq holatda ushlab turadi.

● Harakat plitasida o'zaro 180 daraja aylanish stoli.Ikkita qolipni o'rnatishi mumkin, bu ikki xil rangdagi mahsulotni ishlab chiqaradi.

● Yagona in'ektsiya tsilindri in'ektsiyani yanada barqaror va aniqroq qiladi.

● In'ektsiya chiziqli yo'riqnomasi tufayli aniq qo'llanma bilan past ishqalanish qarshiligi.

● Barcha o'lchamdagi in'ektsiya moslamasi uchun maxsus dizayndagi barcha vintlar L:D=20:1 oson o'zgarishi mumkin. Barcha mijozning maxsus talablariga mos kelishi mumkin.

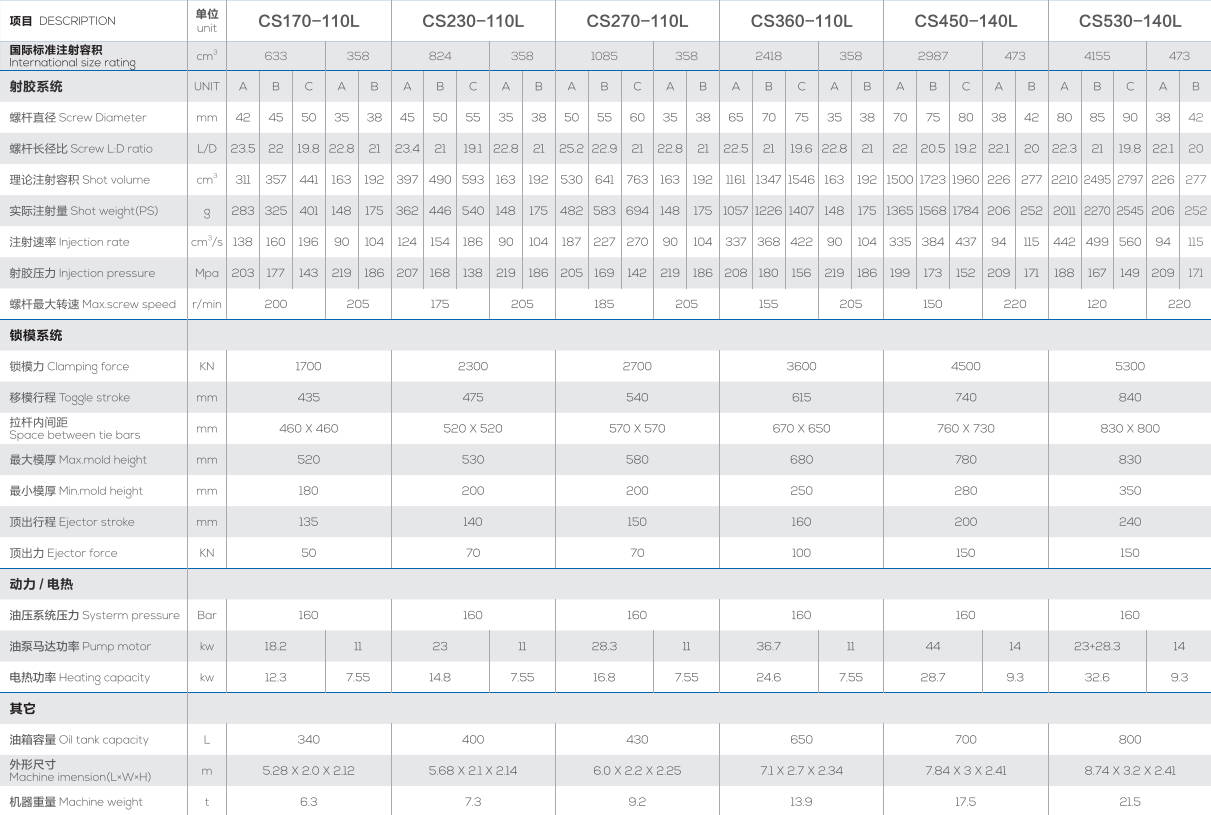

XUSUSIYATLAR

| TAVSIF | birlik | CPS150 o'qi | CPS230 o'qi | ||||||||||||||||||||||

| IN'EKSIYA BIRLIGI | A | B | A | B | A | B | A | B | |||||||||||||||||

| Vida diametri | mm | 28 | 32 | 28 | 32 | 32 | 40 | 32 | 40 | ||||||||||||||||

| LD aylanishini burang | L/D | 22.5 | 22.5 | 22.5 | 22.5 | 22.5 | 20 | 22.5 | 20 | ||||||||||||||||

| Otish hajmi | sm³ | 108 | 141 | 108 | 141 | 141 | 220 | 141 | 220 | ||||||||||||||||

| Otish nuri (PS) | g | 98 | 128 | 98 | 128 | 128 | 200 | 128 | 200 | ||||||||||||||||

| oz | 3.5 | 4.5 | 3.5 | 4.5 | 4.5 | 7.1 | 4.5 | 7.1 | |||||||||||||||||

| Inyeksiya bosimi | Bar | 2699 | 2066 | 2699 | 2066 | 2640 | 1690 | 2640 | 1690 | ||||||||||||||||

| in'ektsiya tezligi | sm³/s | 79 | 83 | 79 | 83 | 83 | 129 | 83 | 129 | ||||||||||||||||

| Kapuotni plostizatsiya qilish | g/s | 9 | 10 | 9 | 10 | 12 | 18 | 12 | 18 | ||||||||||||||||

| in'ektsiya zarbasi | mm | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | ||||||||||||||||

| In'ektsiya tezligi | mm/s | 120 | 120 | 120 | 120 | 103 | 103 | 103 | 103 | ||||||||||||||||

| Maksimal vida tezligi | r/min | 221 | 221 | 221 | 221 | 221 | 221 | 221 | 221 | ||||||||||||||||

| QISQOVCHI BIRLIK | |||||||||||||||||||||||||

| Siqish kuchi | KM | 1500 | 2300 | ||||||||||||||||||||||

| Ochilish zarbasi | mm | 445 | 475 | ||||||||||||||||||||||

| Chiziqlar orasidagi bo'shliq | mm | 470x470 | 520x520 | ||||||||||||||||||||||

| Qolib balandligi (Maks-Min) | mm | 180 ~ 520 | 200 ~ 530 | ||||||||||||||||||||||

| Ejektor zarbasi | mm | 70 | 80 | ||||||||||||||||||||||

| Ejektor zarbasi | mm | 140 | 140 | ||||||||||||||||||||||

| Ejektor soni | dona | lX2 | lX2 | ||||||||||||||||||||||

| Masofadagi Berrel markazlari | mm | 280 | 300 | ||||||||||||||||||||||

| Quvvat birligi | |||||||||||||||||||||||||

| Tizim bosimi | Bar | 160 | 160 | ||||||||||||||||||||||

| Nasosli dvigatel | KW | 14 | 14 | 14 | 14 | ||||||||||||||||||||

| Isitish quvvati | KW | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | ||||||||||||||||

| Temp zonalari soni | 2X4 | 2X4 | |||||||||||||||||||||||

| BOSHQALAR | |||||||||||||||||||||||||

| Neft tankining sig'imi | L | 400 | 460 | ||||||||||||||||||||||

| Mashina o'lchami (L xWxH) | m | 5,0X1,43X2,1 | 5.68X1.53X 2.14 | ||||||||||||||||||||||

| Mashinaning og'irligi | t | 6 | 7 | ||||||||||||||||||||||

| Hopper sig'imi | kg | 25 | 25 | 25 | 25 | ||||||||||||||||||||

| TAVSIF | birlik | CPS170 | CPS280 | CPS320 | CPS400 | CPS450 | CPS850 | ||||||||||||||||||

| IN'EKSIYA BIRLIGI | A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B | A | B | |

| Vida diametri | mm | 28 | 32 | 28 | 32 | 28 | 32 | 32 | 40 | 32 | 40 | 40 | 45 | 40 | 45 | 40 | 45 | 40 | 45 | 40 | 45 | 40 | 50 | 50 | 55 |

| LD aylanishini burang | L/D | 22.5 | 22.5 | 22.5 | 22.5 | 22.5 | 22.5 | 22.5 | 20 | 22.5 | 20 | 23 | 20.5 | 23 | 20.5 | 23 | 20.5 | 23 | 20.5 | 23 | 20.5 | 23 | 20.5 | 20 | 20 |

| Otish hajmi | sm³ | 108 | 141 | 108 | 141 | 108 | 141 | 141 | 219 | 141 | 219 | 283 | 358 | 283 | 358 | 283 | 358 | 283 | 358 | 283 | 358 | 283 | 442 | 442 | 535 |

| Otish nuri (PS) | g | 98 | 128 | 98 | 128 | 98 | 128 | 128 | 199 | 128 | 199 | 257 | 326 | 257 | 326 | 257 | 326 | 257 | 326 | 257 | 326 | 257 | 402 | 402 | 486 |

| oz | 3.5 | 4.5 | 3.5 | 4.5 | 3.5 | 4.5 | 4.5 | 7 | 4.5 | 7 | 9.1 | 11.5 | 9.1 | 11.5 | 9.1 | 11.5 | 9.1 | 11.5 | 9.1 | 11.5 | 9.1 | 14.2 | 14.2 | 17.2 | |

| Inyeksiya bosimi | Bar | 2699 | 2066 | 2699 | 2066 | 2699 | 2066 | 2066 | 1322 | 2066 | 1322 | 1960 yil | 1549 | 1960 yil | 1549 | 1960 yil | 1549 | 1960 yil | 1549 | 1960 yil | 1549 | 1960 yil | 1254 | 1638 | 1354 |

| in'ektsiya tezligi | sm³/s | 79 | 83 | 79 | 83 | 99 | 121 | 121 | 112 | 131 | 141 | 171 | 216 | 171 | 216 | 171 | 216 | 218 | 274 | 218 | 274 | 218 | 340 | 326 | 394 |

| Kapuotni plostizatsiya qilish | g/s | 9 | 10 | 9 | 10 | 11 | 12 | 12 | 18 | 12 | 18 | 29 | 29 | 29 | 29 | 29 | 29 | 29 | 29 | 29 | 29 | 27 | 48 | 48 | 59 |

| in'ektsiya zarbasi | mm | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 175 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 | 225 |

| In'ektsiya tezligi | mm/s | 120 | 120 | 120 | 120 | 150 | 150 | 150 | 150 | 190 | 190 | 136 | 136 | 136 | 136 | 136 | 136 | 173 | 173 | 173 | 173 | 173 | 173 | 166 | 166 |

| Maksimal vida tezligi | r/min | 221 | 221 | 221 | 221 | 250 | 250 | 250 | 250 | 280 | 280 | 250 | 250 | 250 | 250 | 250 | 250 | 300 | 300 | 300 | 300 | 300 | 300 | 300 | 300 |

| QISQOVCHI BIRLIK | |||||||||||||||||||||||||

| Siqish kuchi | KM | 1700 | 2800 | 3200 | 4000 | 4500 | 8500 | ||||||||||||||||||

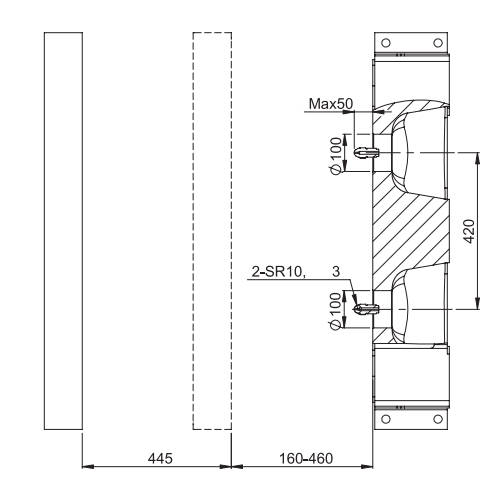

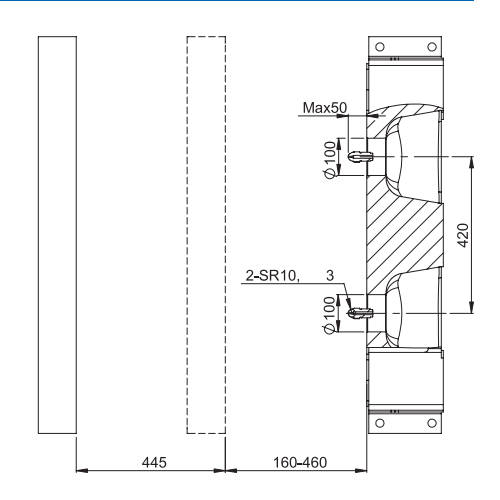

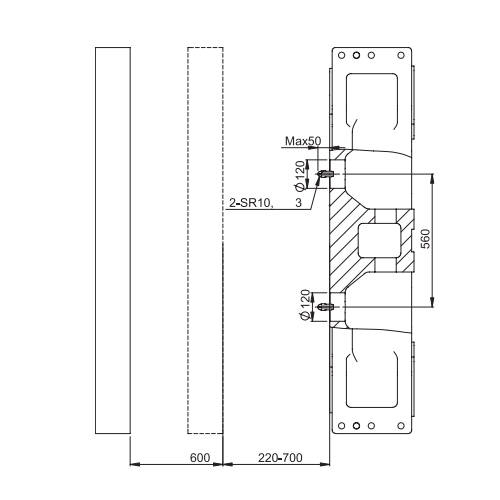

| Ochilish zarbasi | mm | 445 | 460 | 460 | 600 | 600 | 1000 | ||||||||||||||||||

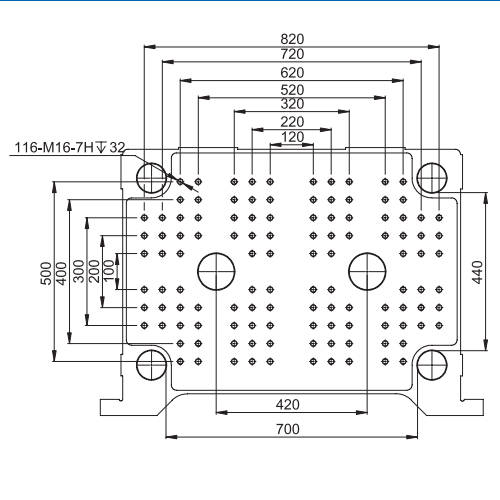

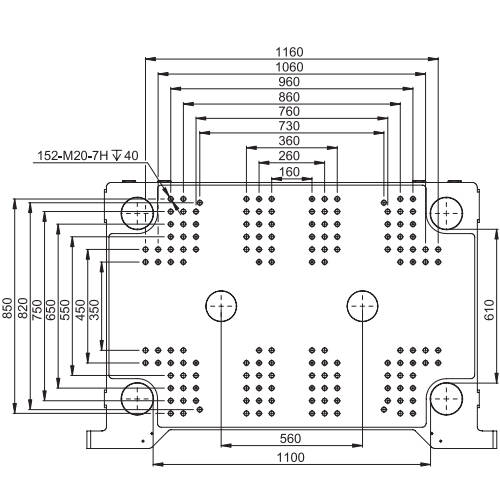

| Chiziqlar orasidagi bo'shliq | mm | 700 X 440 | 910 X 570 | 910 X 570 | 1100X610 | 1100X610 | 1060X1010 | ||||||||||||||||||

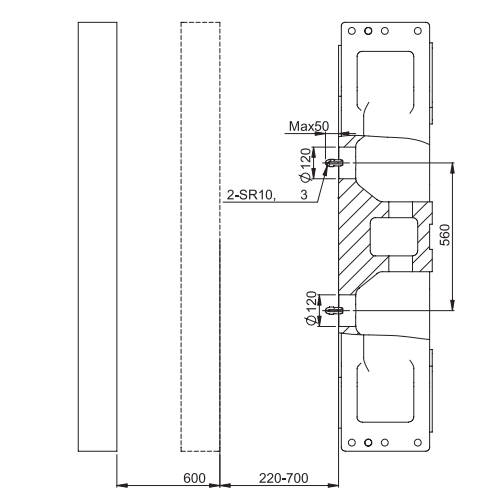

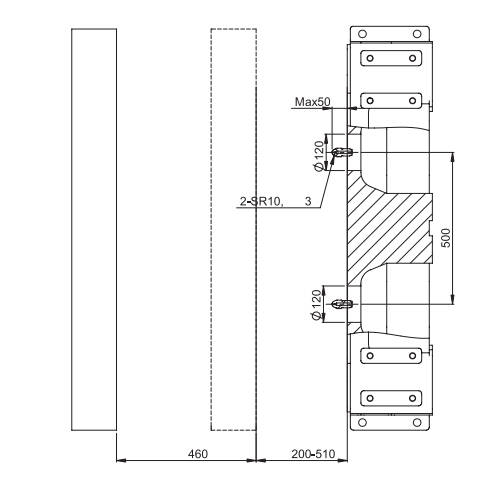

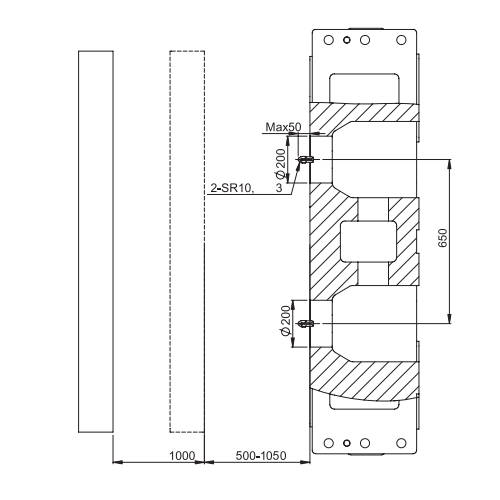

| Qatlam balandligi (Min-Maks) | mm | 160 ~ 460 | 200 ~ 510 | 200 ~ 510 | 220 ~ 700 | 220 ~ 700 | 500 ~ 1050 | ||||||||||||||||||

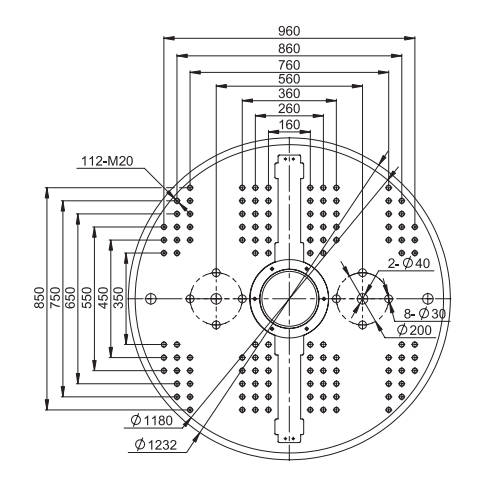

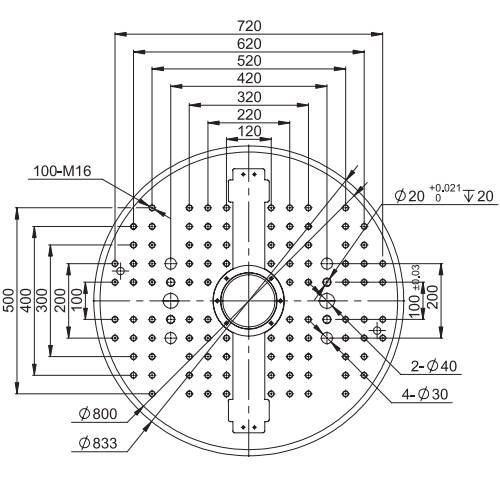

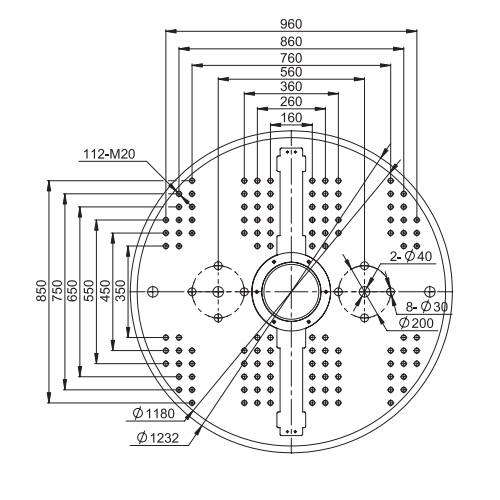

| Aylanadigan stol diametri | mm | 800 | 1000 | 1020 | 1150 | 1180 | 1530 | ||||||||||||||||||

| Ejektor zarbasi | mm | 100 | 140 | 140 | 140 | 140 | 130 | ||||||||||||||||||

| Ejektor kuchi | dona | 38X2 | 53X2 | 53X2 | 70X2 | 70X2 | 70X2 | ||||||||||||||||||

| Ejektor soni | mm | 3X2 | 3X2 | 3X2 | 5X2 | 5X2 | 5X2 | ||||||||||||||||||

| Masofadagi Berrel markazlari | 420 | 500 | 500 | 560 | 560 | 650 | |||||||||||||||||||

| Quvvat birligi | |||||||||||||||||||||||||

| Tizim bosimi | Bar | 160 | 160 | 160 | 160 | 160 | 160 | ||||||||||||||||||

| Nasosli dvigatel | KW | 14 | 14 | 18.2 | 18.2 | 23 | 23 | 23 | 23 | 28.3 | 28.3 | 28.3 | 36.7 | ||||||||||||

| Isitish quvvati | KW | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 6.8 | 12.3 | 12.3 | 6.8 | 6.8 | 12.3 | 12.3 | 12.3 | 12.3 | 12.3 | 12.3 | 12.3 | 12.3 | 17.3 | 17.3 |

| Temp zonalari soni | 2X4 | 2X4 | 2X4 | 2X4 | 2X4 | 2X5 | |||||||||||||||||||

| BOSHQALAR | |||||||||||||||||||||||||

| Neft tankining sig'imi | L | 400 | 460 | 500 | 650 | 700 | 1100 | ||||||||||||||||||

| Mashina o'lchami (L xWxH) | m | 5,0X1,76X 2,1 | 5,0X1,76X 2,1 | 6,1X2,1X2,2 | 6,8X2,37X2,3 | 7,0X2,0X2,0 | 11,2X3,05X2,75 | ||||||||||||||||||

| Mashinaning og'irligi | t | 7.1 | 12 | 12.5 | 20 | 20.5 | 48 | ||||||||||||||||||

| Hopper sig'imi | kg | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | ||||||||||||

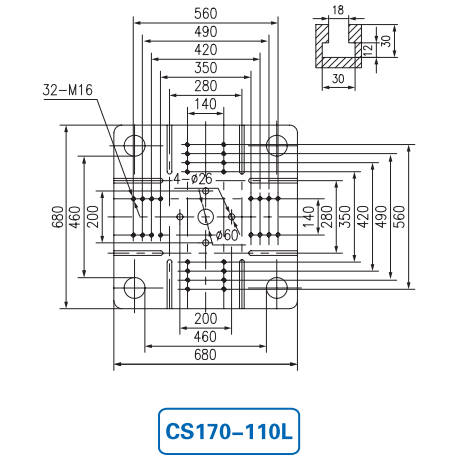

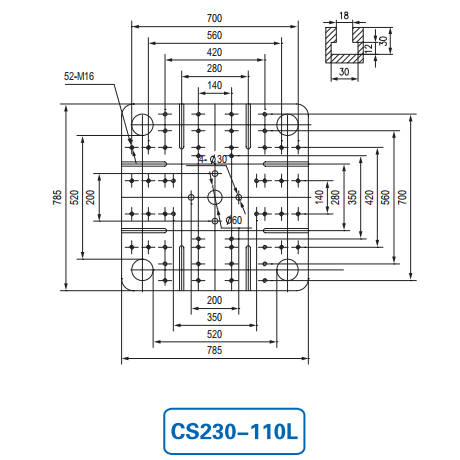

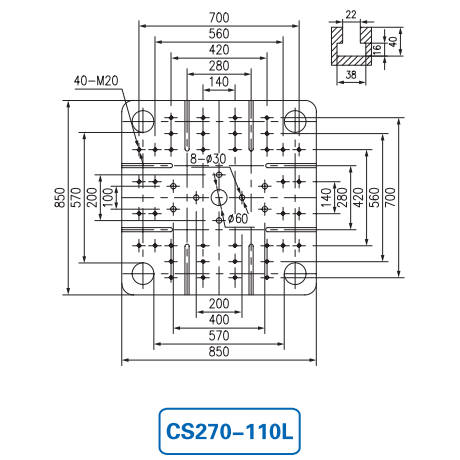

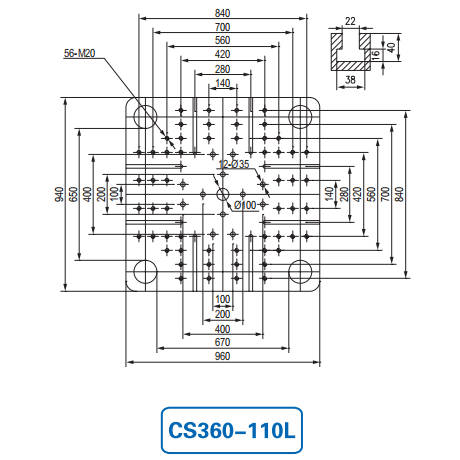

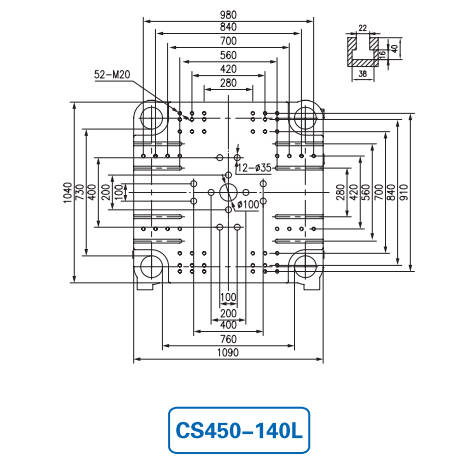

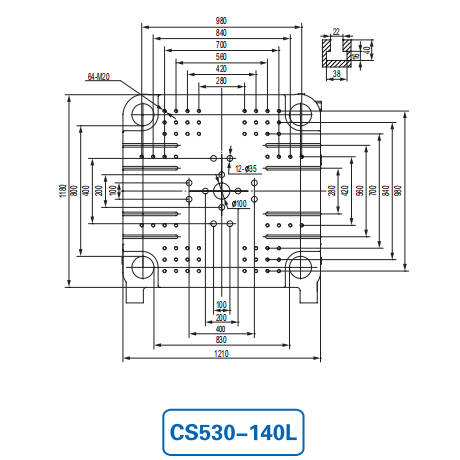

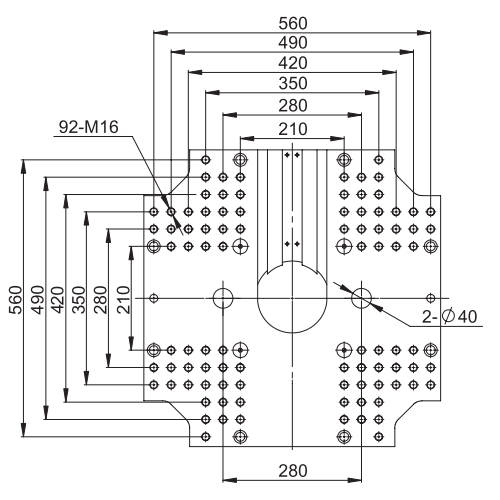

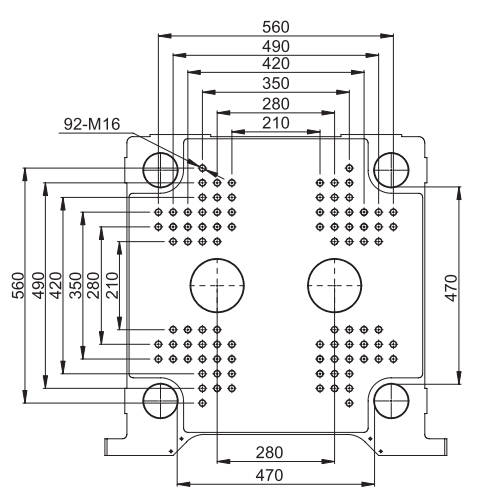

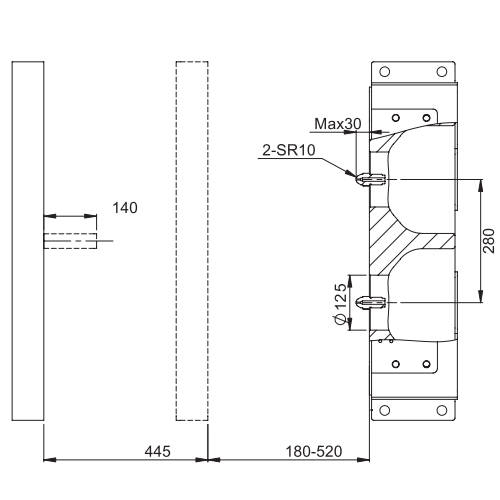

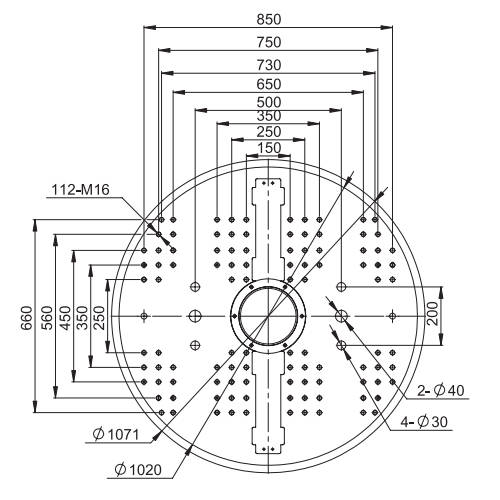

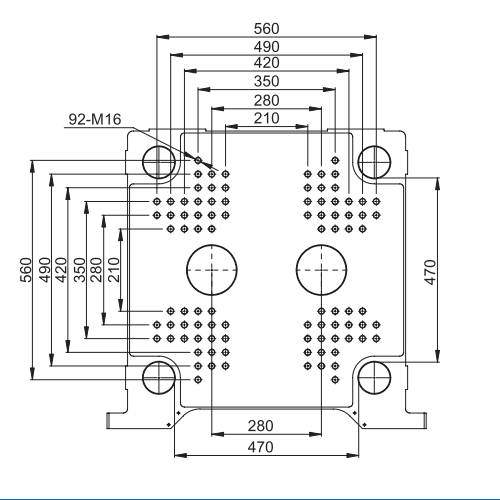

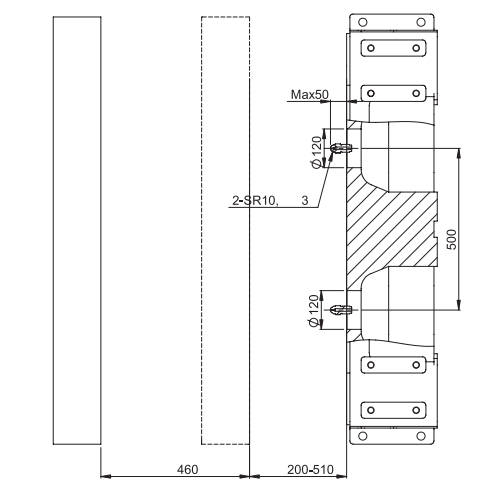

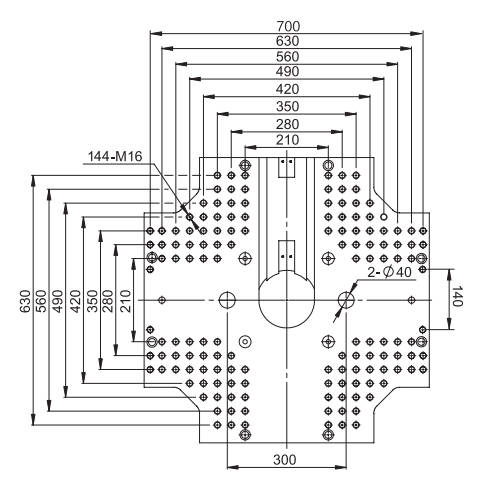

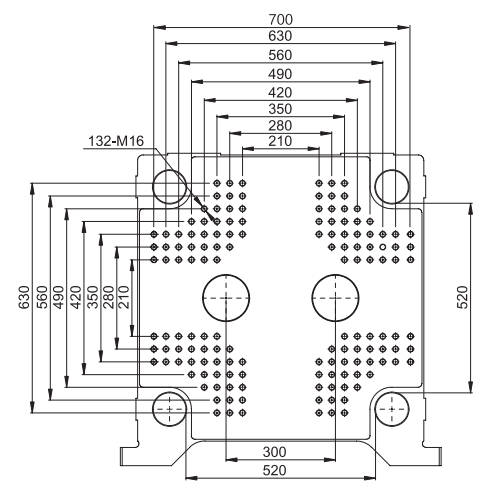

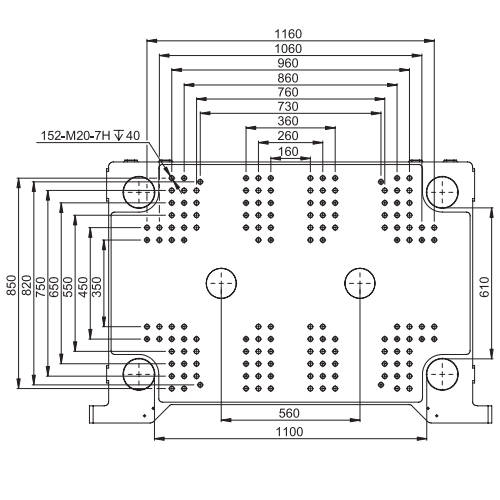

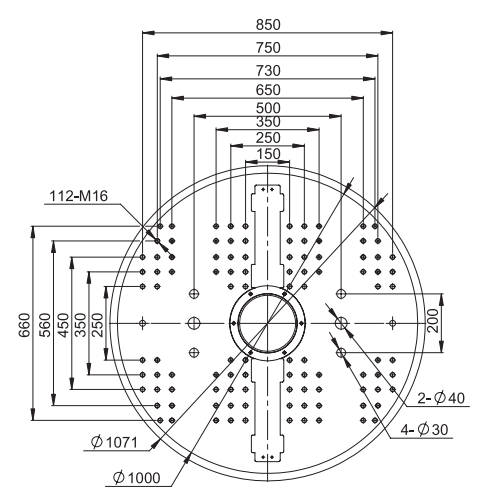

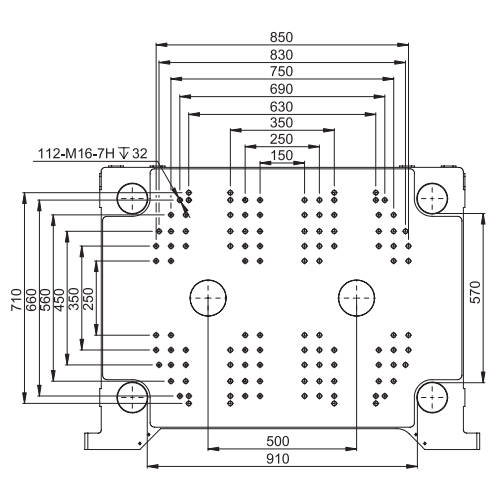

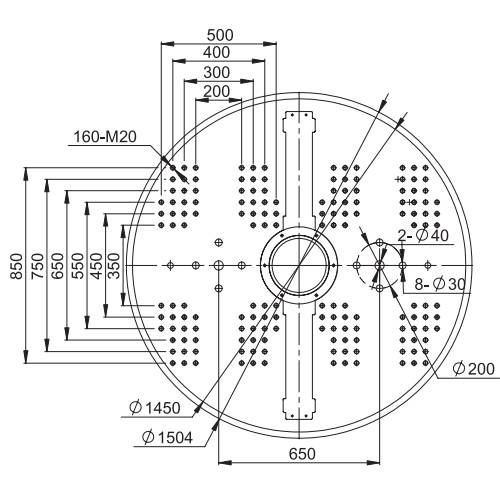

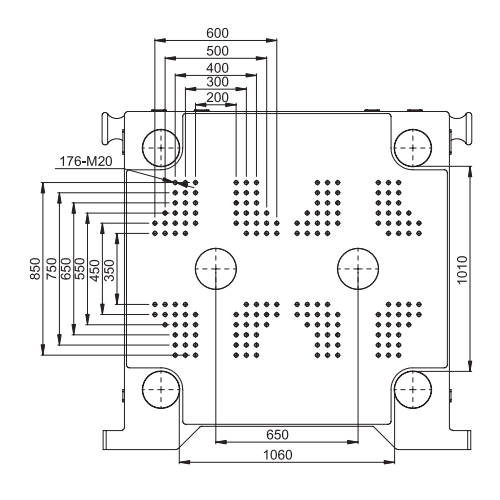

Shablon tekislik diagrammasi

■

CPS150 o'qi

■

CPS320

■

CPS230 o'qi

■

CPS400

■

CPS170

■

CPS450

■

CPS280

■

CPS850

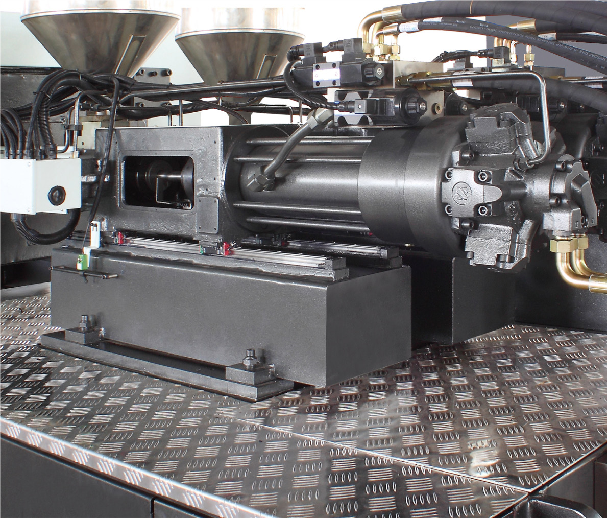

L modeli toza ikki rang

● Ikki in'ektsiya birligi toza ikki rang uchun L dizayni bo'lishi kerak.

● Harakat plitasida o'zaro 180 daraja aylanish stoli. Bitta qolipni o'rnatish ikki xil rangdagi mahsulotni ishlab chiqarishi mumkin.

● Samarali servo tishli uzatish tuzilishi barqaror va aniq pozitsiya bilan yuqori tezlikda aylanishni davom ettiradi.

● Ko'p plastinkali dizayn barcha mahsulotlarning aylanish stoliga yoki aylanish miliga mos kelishi mumkin.

● Aylanadigan patnis ishlayotganda qisqichga tegmasdan.Aşınma tufayli nosozlikni kamaytirishi mumkin.Qoliplarni yopishdan oldin aniq joylashish qoliplarning xavfsizligini ta'minlaydi.

CS230-IIOL

Shablon o'lchami